3 Patented Designs That Simplify Structured Cabling Installation

2025/10/29 HCIBehind every sleek patch panel and every toolless keystone jack are hundreds of design decisions aimed at solving one universal pain point: how to make installations faster, cleaner, and more reliable without sacrificing long-term performance.

Today, we’re taking you behind the scenes of three U.S.-patented mechanical designs that represent years of engineering refinement and field insight. These inventions help integrators, contractors, and distributors deliver structured cabling systems that are smarter, safer, and easier to manage.

1. The Front-Access Patch Panel (U.S. 7,278,880 B1)

Every installer knows the frustration of trying to terminate jacks in the shadows of a fully populated rack. Tight clearances, tangled cables, and poor visibility can turn a simple patch job into a time-consuming challenge.

HCI’s SP24F2 series Front-Access Patch Panel, protected under U.S. Patent 7,278,880 B1, was engineered to eliminate that pain point. Its modular 6-port design allows technicians to remove, terminate, and reinstall each module directly from the front of the rack, no need to unmount or access the rear.

This design changes the way structured cabling is maintained:

Front accessibility makes re-termination and testing easier in dense environments.

Hinged covers and removable bezels allow bulk cables to be pulled or organized from the rear, even when the panel is mounted.

Integrated wire management keeps terminations neat and ensures consistent bend radius control.

For installers, it means fewer interruptions and a cleaner workflow. For distributors and project managers, it means a design that adds tangible value to any rack system.

Watch the 3D installation video here:

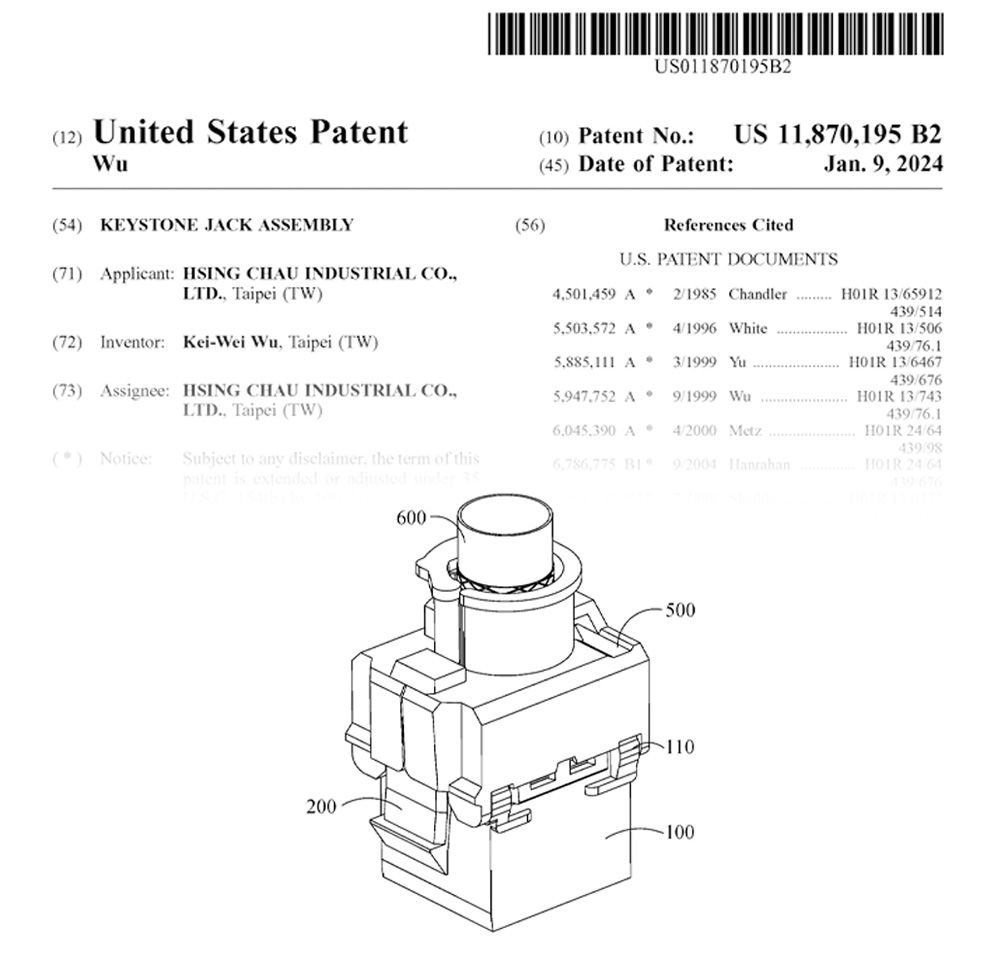

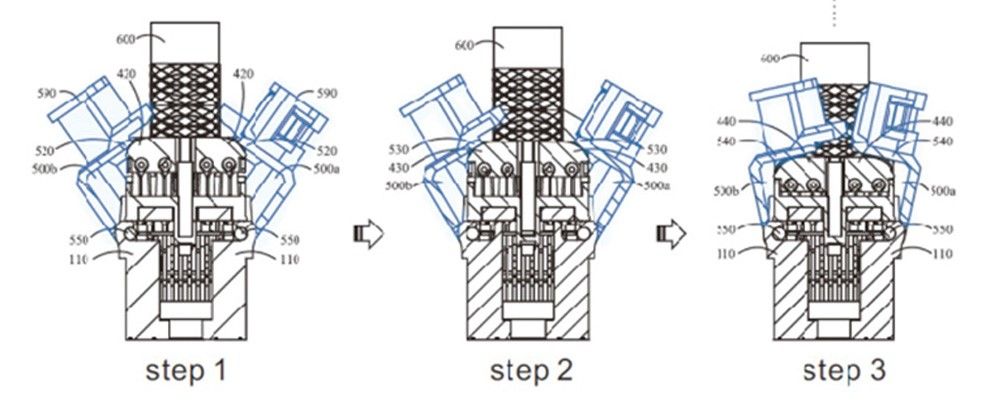

2. The 3-Step Progressive Mechanism (U.S. 11,870,195 B2)

The redesign of our toolless keystone jack focused on turning a repetitive task into a simple, precise action. The result was the 3-step progressive termination system, patented under U.S. Patent 11,870,195 B2.

Traditional toolless designs often rely on tight spring tension or extra force to close the housing, which can fatigue the installer’s fingers and risk uneven terminations. HCI’s design solves this with a progressive compression sequence that activates the IDC (insulation displacement contact) gradually in three controlled stages.

Here’s what makes it different:

The wire-loaded cap aligns conductors precisely before closure.

Dual-side finger pressure locks the cap and engages the IDC terminals evenly

The compact, short-body form factor minimizes length while maintaining a full 360° shielding path for EMI protection.

This mechanism, used in HCI’s Shortbody Toolless Keystone Jack series (LKHB, LKHBD, LKHBS, LKHBSD), improved speed and consistency through ergonomic precision.

3. The Frame-with-Shutter System (U.S. 12,051,872 B2)

Shielded connectors offer superior EMI protection, but they come with one design compromise: color identification. The TIA-606 standard recommends color-coding for specific LAN fields. While plastic jacks can be easily color-coded, die-cast housings, common in shielded models, cannot.That limitation leads to confusion during installation and maintenance, especially in high-density racks.

HCI’s Frame-with-Shutter design (U.S. Patent 12,051,872 B2) solves this elegantly. The front frame integrates both:

Color marking areas for instant identification, and

A spring-loaded shutter that closes automatically when the plug is removed, keeping out dust and debris.

This integrated approach simplifies color identification while providing protection for STP keystone jacks from dust and debris. This innovation is featured in the LKVASD and LKHBSD series.

Why Mechanical Patents Matter

While these patents focus on mechanical design rather than signal transmission, they play a crucial role in maintaining end-to-end performance stability. In a 10G and PoE++ environment, mechanical integrity is electrical integrity.

Every precisely machined latch, shutter, and termination cap contributes to consistent contact pressure, stable geometry, and long-term reliability under repeated use. For OEM and ODM partners, patented mechanical design also means differentiation, and the confidence that the solution they integrate carries not only a proven structure, but also intellectual protection and field-tested innovation.

📬 For more articles like this, subscribe to our newsletter! Click to sign up here