MPO

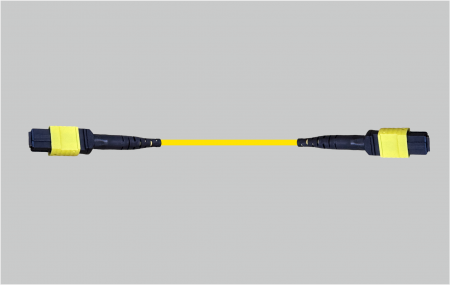

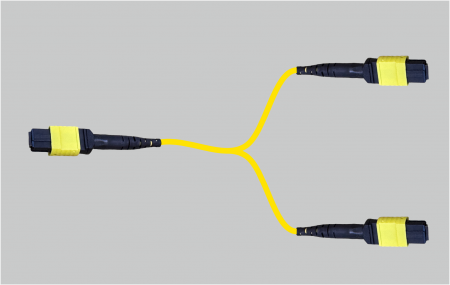

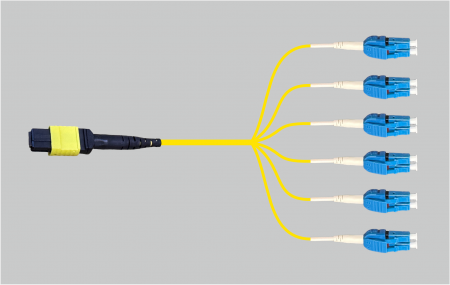

Array Cable / Breakout

MPO cables are a cornerstone of modern data center infrastructure, enabling multi-lane, high-density inter- and intra-connections between data centers and distribution points. The main advantage of MPO connectors is their high density, housing 12, 16, or more fibers in a single ferrule. This simplifies cable management and improves airflow in racks, directly supporting equipment cooling and overall energy efficiency.

Parallel optics running on MPO are powerful but not as straightforward as LC duplex, which is typically a simple plug-and-play connection. Due to this added complexity, selecting the right MPO cable requires careful attention to detail. Before deployment, here are some key specifications to consider:

Number of Fibers

While MPO connectors come in various fiber counts, the most common are MPO-12 and MPO-16. An MPO-12 connector can hold up to 12 fibers, but it’s often used in 8-fiber applications like 400G-SR4, where four fibers are for transmit and four are for receive, leaving four fibers unused. MPO-16 connectors are purpose-built for 8-lane transmission, making them ideal for high-speed standards like 800G-SR8.MPO vs. MTP®

MPO is the industry standard for this type of connector, but MTP® is a brand name for a high-performance MPO connector manufactured by US Conec. All MTPs are MPOs, but not all MPOs are MTPs. MTP® connectors feature precision-engineered upgrades for better optical and mechanical performance, including elliptical guide pins that enhance alignment accuracy and a metal clamp that boosts alignment consistency.Male vs. Female Connectors

Proper mating of two MPO connectors requires a male-to-female connection. MPO male connectors have two small guide pins that ensure precise fiber alignment with the guide holes in the female connector. Since optical modules like transceivers always have built-in male connectors with guide pins, the MPO cable end that connects to the transceiver must be female.Keying

The key is a small protrusion on the MPO connector that ensures proper orientation, either Key Up or Key Down. Its precise position, along with the white dot on the connector body, clearly identifies Fiber Position 1, which is critical for correct polarity and proper alignment of transmit and receive fibers. An MPO adaptor can also be used to flip the key, allowing the parallel optic transmit (TX) fibers to connect to receive (RX) fibers and vice versa.Fiber Polarity

Ensuring correct polarity is often the most complex part of MPO cabling. The most common methods are: Type A (Straight-Through) maps Fiber 1 to 1, 2 to 2, and so on, requiring a polarity flip at the transceiver or with a patch cord. Type B (Reversed) maps Fiber 1 to 12, 2 to 11, etc., letting the cable handle the flip, which makes it the preferred choice for direct transceiver-to-transceiver links.Breakout Types

MPO cables are frequently used as breakout cables, splitting a single multi-fiber connector into two lower-speed MPO connectors or multiple duplex LC connectors. For example, an MPO Y-cable can split a single 400G MPO trunk into two separate 200G MPO connectors. MPO-to-LC breakout cables break a parallel optic link into lower-speed duplex ports, such as an MPO-16 800G trunk splitting into eight 100G LC duplex connectors.Fiber Mode and Wavelength: SMF vs. MMF

The fiber type dictates the maximum transmission distance and wavelength used. Single-Mode Fiber (OS2, 9/125 µm) supports long-reach links at 1310 nm or 1550 nm. Multimode Fiber has a larger core for short-reach data center use. Common types include OM3, OM4, and OM5, which supports broader wavelengths. Multimode Fiber typically operates at 850 nm, and in some BiDi applications, transmission may extend to around 910 nm.Polish Type: UPC vs. APC

The polish on a connector’s end face affects light reflection. UPC has a 0° polish, reflecting light straight back to the source. It offers a return loss of -50 dB or better and is commonly used with multimode fiber. APC is polished at 8°, directing reflections into the cladding and reducing back reflection. With a return loss of -65 dB or better, APC is standard for single-mode fiber. And UPC and APC types should never be mated.Breakout Length: The Fanout

The fanout length is the length of the individual breakout legs in a harness cable. Specifying it correctly prevents excess slack that clutters a rack or legs too short to reliably reach their intended ports or devices. Typical fanout lengths are 0.3 m for MPO breakout and 0.6 m for LC breakout, with fully customizable options available to match different cabinet layouts and installation requirements.MPO parallel optics drive hyperscale data centers with 400G and 800G solutions. We know there are plenty of variations out there, so customization is always welcome. Browse the main section, let us know what you want tweaked, and HCI is here to help!