When Fiber Is Too Expensive and 100m Isn't Enough

2025/12/29 HCIFor over two decades, 100 meters has been the standard limit for Ethernet over copper. But that limit was a design choice based on Category 5 cable performance in the late 1990s.

Today, the reality looks very different.

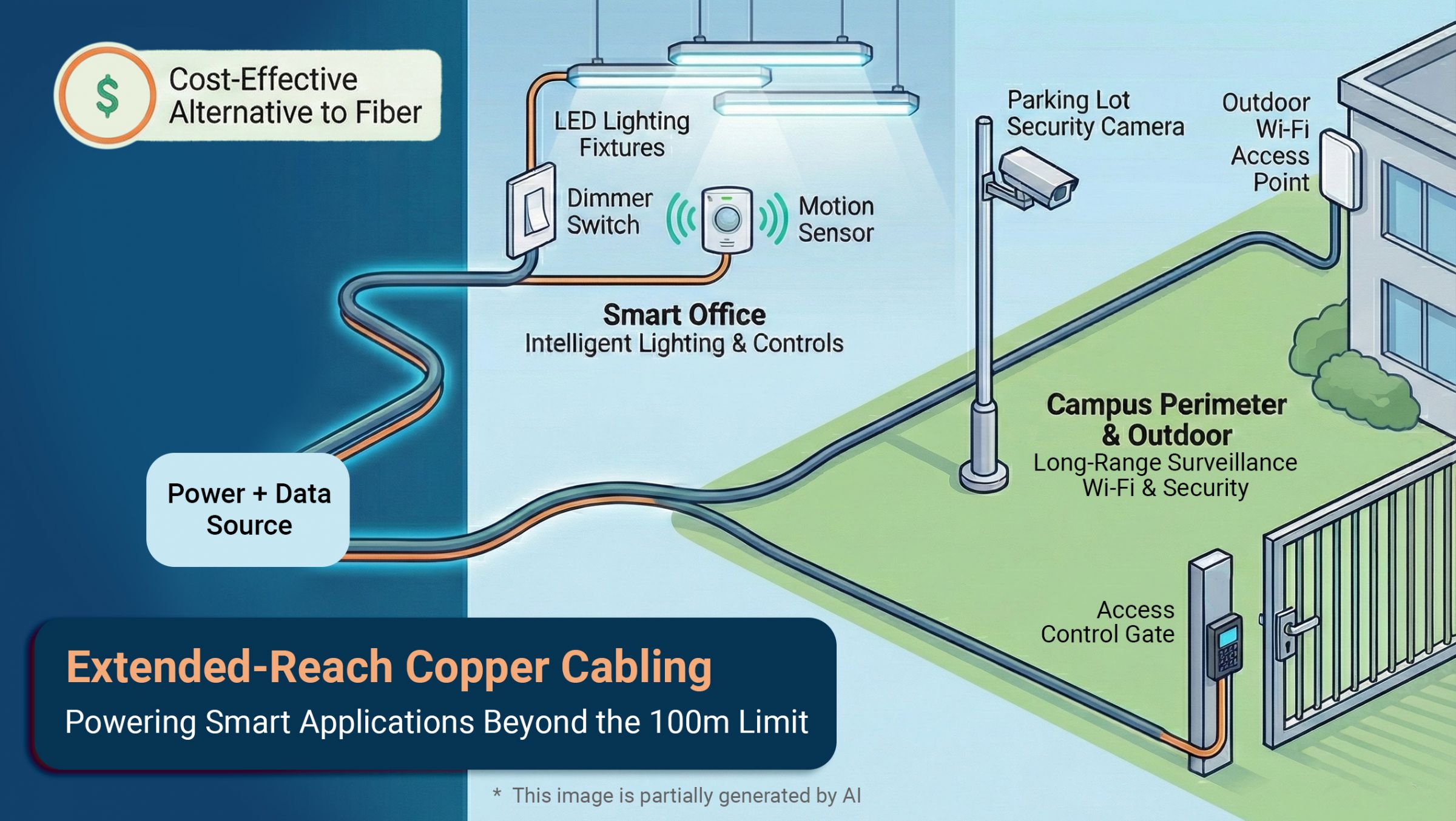

Parking lot cameras sit 150 meters from the nearest telecom room. Perimeter Wi-Fi access points need power and data 200 meters away. Building entrance access control systems are regularly deployed beyond the 100-meter mark.

When fiber trenching costs 10× more and installing intermediate telecom rooms isn’t practical, extended-reach copper becomes the solution.

Major brands have already launched 200-meter copper solutions. Extended-distance limits are now built into field certifiers. UL-verified systems are on the market. Copper has moved beyond 100 meters, and it’s already deployed in real projects.

Understanding the Distance Effect

Once copper cabling extends beyond 100 meters, several physical constraints appear together.

-

Distance increases → Speed must decrease

Longer cable runs cause greater signal attenuation. To maintain reliable transmission over extended distances, link speed must be reduced. This is a physical limitation, not a tuning issue. -

Distance increases → DC resistance increases

Even with the same conductor gauge, longer cables have higher resistance. This impacts both signal integrity and power delivery. -

Higher resistance → PoE delivery becomes constrained

Voltage drop increases with distance, limiting how much power actually reaches the end device. This is often the first failure point in extended runs.

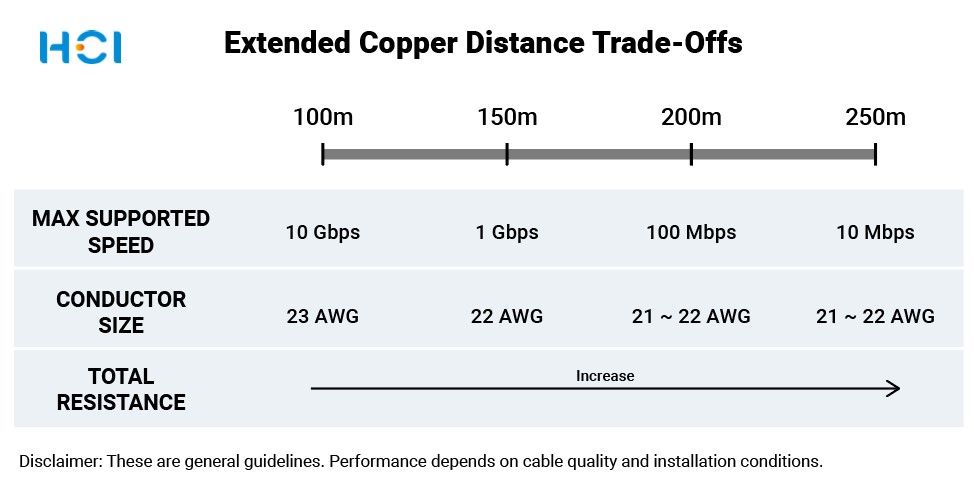

The Three Trade-Offs That Make Extended Reach Possible

1. Conductor Size

Extended-reach solutions typically rely on thicker conductors such as 22 AWG or 21 AWG instead of the more common 23 AWG.

The larger copper cross-section lowers DC resistance per meter. This helps preserve signal quality at reduced speeds and improves PoE power delivery over longer distances.

The trade-off is mechanical. Larger gauge cables are stiffer, require more bend radius, and take up more space in pathways and enclosures. Connector and jack compatibility also becomes more limited, which can increase installation complexity in dense environments.

2. Speed Trade-Offs

Extended-reach links usually operate between 100 to 250 meters, with speeds ranging from 1 Gbps at shorter distances down to 10 Mbps at the longest runs.

For example, a parking lot camera streaming 1080p video typically needs only 20–30 Mbps. At 150 meters with 1 Gbps capability, there is plenty of performance headroom. Pushing further requires careful alignment between cable type, speed, and device requirements.

3. Thermal Management Under PoE Load

PoE current generates heat. As distance increases, DC resistance rises and so does thermal buildup. At 150 meters with PoE++ (90W), cable temperature becomes a real design constraint.

Well-designed extended-reach deployments account for:

- Ambient temperature

- Cable bundle size and heat dissipation

- PoE wattage required by the device

- DC resistance unbalance between pairs

Application Guidance: When to Specify Extended Reach

Ideal applications include:

- IP surveillance cameras in outdoor or remote locations

- Perimeter wireless access points

- Access control systems for gates, entrances, and parking areas

- LED lighting control systems

- Environmental and IoT sensors with low bandwidth demand

We’re also expanding our solution set for IoT deployments with a highly efficient outdoor PV energy harvesting option, designed for low-power devices where PoE isn’t practical. More on this soon.

Not suitable for:

- Backbone infrastructure or future-proof links

- High-density switch interconnects

- Applications that require full-speed upgrade paths later

Extended reach always trades speed for distance. That trade cannot be reversed later.

Before specifying extended reach, the key question is simple:

Does this specific device, at this power level, in this environment, justify the trade-offs?

Planning an Extended-Reach Deployment?

Our team can help you evaluate transmission requirements, connector compatibility, PoE or PoE++ constraints, and whether cabling-based or PV-assisted power makes more sense for your indoor or outdoor application.

Contact us: hci@hci.com.tw